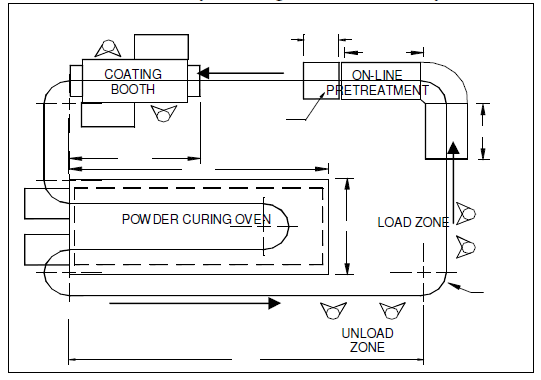

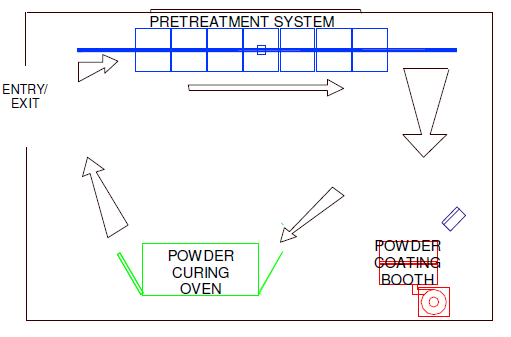

Powder coating process is a simple process requiring minimal skills and training The articles to be coated are first cleaned of all foreign matter from the surface, aluminum plates or components go through a chromate conversion coating. This, known as pre-treatment, is employed for improved bonding of the powder coat to the materials being coated to provede a long life to the coat. The method employed usually is a dip in chemicals and water in various tanks. Occasionally, the process may be automated through a spray pretreatment process.

Signi Batch powder coating system :

The ‘pretreated’ aluminum plate sheet are jigged and hung into the

coating booth on a fixed or rotatable jig-holder. The manual coater

coats the components from all sides. The aluminum plate sheet are then

moved out onto an oven trolley (or directly into the oven). The trolley,

if used, is

rolled into the oven when full. In the oven, at a temperature of

180-220oC, in 10-15 minutes, the

powder melts, polymerizes fuses and cures into the final tough uniform

and consistent powder coat that has high aesthetic value. At the end of

the curing schedule, the trolley is rolled out of the oven and allowed

to cool down. The articles are then removed out from the paint-shop.